Nambu Tekki|The 400-Year-Old “Usable Art” from Iwate

Born in the land of Tohoku, Iwate, Nambu Tekki (Southern Ironware) represents the harmony of Japanese craftsmanship and everyday beauty.

Developed along with the tea ceremony culture during the Edo period, this ironware continues to live on in the regions of Morioka and Oshu today, loved around the world as kettles, pots, wind chimes, and even accessories.

What Is Nambu Tekki

Nambu Tekki is a traditional metal craft made in Morioka City and Mizusawa in Oshu City, Iwate Prefecture.

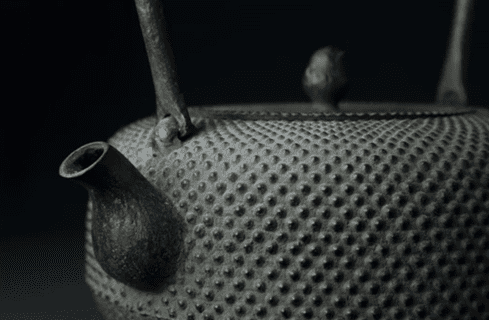

It originated during the 17th century under the Nambu domain and is known as a “usable artwork” for its rich iron texture and excellent practicality.

Its main features include even heat distribution, high heat retention, and resistance to rust even after long use. The rough surface texture is unique, and the representative Arare (hailstone) pattern not only adds beauty but also increases the surface area to enhance heat efficiency.

In addition to iron kettles, craftsmen also produce pots, wind chimes, cutlery, and even accessories that fit modern lifestyles.

History|The Iron Culture That Began with Tea Kettles

The origin of Nambu Tekki dates back to 1659, when the lord of the Nambu domain invited Koizumi Nizaemon, a kettle master from Kyoto.

Morioka was rich in iron sand and clay, making it an ideal place for casting. The Koizumi family’s kettle making became an official duty for the domain, and later a smaller version for household use, the Nambu Tetsubin (iron kettle), was created.

During the Meiji period, the 8th generation Koizumi Nizaemon presented an iron kettle to the Crown Prince (later Emperor Taisho), and the craftsmanship was widely reported in newspapers, spreading its fame nationwide.

Today, Morioka’s Nambu Tekki and Oshu Mizusawa’s Mizusawa Ironware are the two main production centers carrying on the tradition.

Production Process|The Result of Hundreds of Handmade Steps

The production of Nambu Tekki involves over ten detailed steps, each requiring precision and experience.

- Design and Pattern Creation

The design of the ironware is decided, and based on the plan, a wooden (now metallic) pattern is made. - Mold Making

Sand and clay are layered to form the mold, gradually refining the texture by changing the grain size. - Pattern Stamping and Surface Beating

The iconic “Arare pattern” is stamped one by one. Then, the surface is beaten with sand using brushes or cloth to give it the unique rough texture. - Firing and Casting

The mold is heated to 800–1300°C, and molten iron is poured in — the moment the shape of the ironware is born. - Finishing and Coloring

After cooling, burrs are removed, the surface is polished, and the piece is fired again to create an oxidized film that prevents rust. Finally, lacquer or a mixture of iron rust and tea (called ohaguro) is applied to achieve a deep black color.

Through these extensive processes, it can take several weeks to several months to complete a single iron kettle.

Modern Nambu Tekki|“Usable Art” Spreading Across the World

Today, Nambu Tekki is being re-evaluated as a form of usable art that goes beyond everyday utensils.

Collaborations with tea brands in France and Northern Europe have made “IWACHU” — a manufacturer based in Morioka — synonymous with Nambu Tekki overseas. About one million items are produced each year, and roughly half are exported to Europe and beyond.

In Japan, collaborations with popular characters have been introduced to appeal to younger generations.

Designs featuring characters such as Geodude, Zaku, Snoopy, and Miffy are engraved on the surface of iron kettles, creating a perfect blend of traditional technique and modern culture.

The playful designs within the heavy texture have become symbols of how Japanese tradition continues to evolve in a pop and creative way.

Where to See It|IWACHU Ironware Studio (Morioka)

The IWACHU Ironware Studio offers visitors the opportunity to experience the history and craftsmanship of Nambu Tekki up close.

Along with a gallery exhibition, the facility allows guests to watch real casting processes in a “theme-park-style” workshop, learning the depth and beauty of traditional ironware making.

Address: 2-21-9 Minamisenboku, Morioka City, Iwate Prefecture 020-0863

Hours: 8:30 AM – 5:30 PM

Closed: Tuesdays, December 31, and January 1

Admission: Free

You might also be interested in these articles

■The Bamboo Craft You Never Knew – Quiet Strength Woven into Japanese Life and Luxury

■Japan Denim: Rewriting the Rules of Indigo

What Is Traditional Craftsmanship?

Traditional craftsmanship refers to handmade artworks that have been passed down through generations using time-honored techniques and materials.

Items officially designated as “Traditional Crafts” by Japan’s Minister of Economy, Trade and Industry or by prefectural governors must meet the following criteria:

- They are practical items used in everyday life.

- They are mainly handmade.

- They use traditional materials and techniques.

- They are continuously produced in a specific region and form a local industry.

These conditions ensure that the craft is not only an art form but also a living part of Japan’s cultural heritage.

Editor and writer from Japan. Not the best at English, but I share real stories with heart and honesty — aiming to connect cultures and ideas that matter.